Enabling sheet hydroforming to produce smaller radii on aerospace nickel alloys article pdf available in international journal of material forming october 2018 with 94 reads how we measure.

Hydroforming sheet metal aerospace.

Leading integration of manufacturing and assembly for the aerospace industry.

We maintain certifications and customer approvals in aerospace defense transportation medical power generation and commercial industries.

We ve formed parts for aerospace pioneers like airbus blue origin bell helicopter and lufthansa.

Among the new machinery in jinpao s aerospace division is a triform model 24 5bd fluid cell sheet hydroforming press manufactured by beckwood press co st.

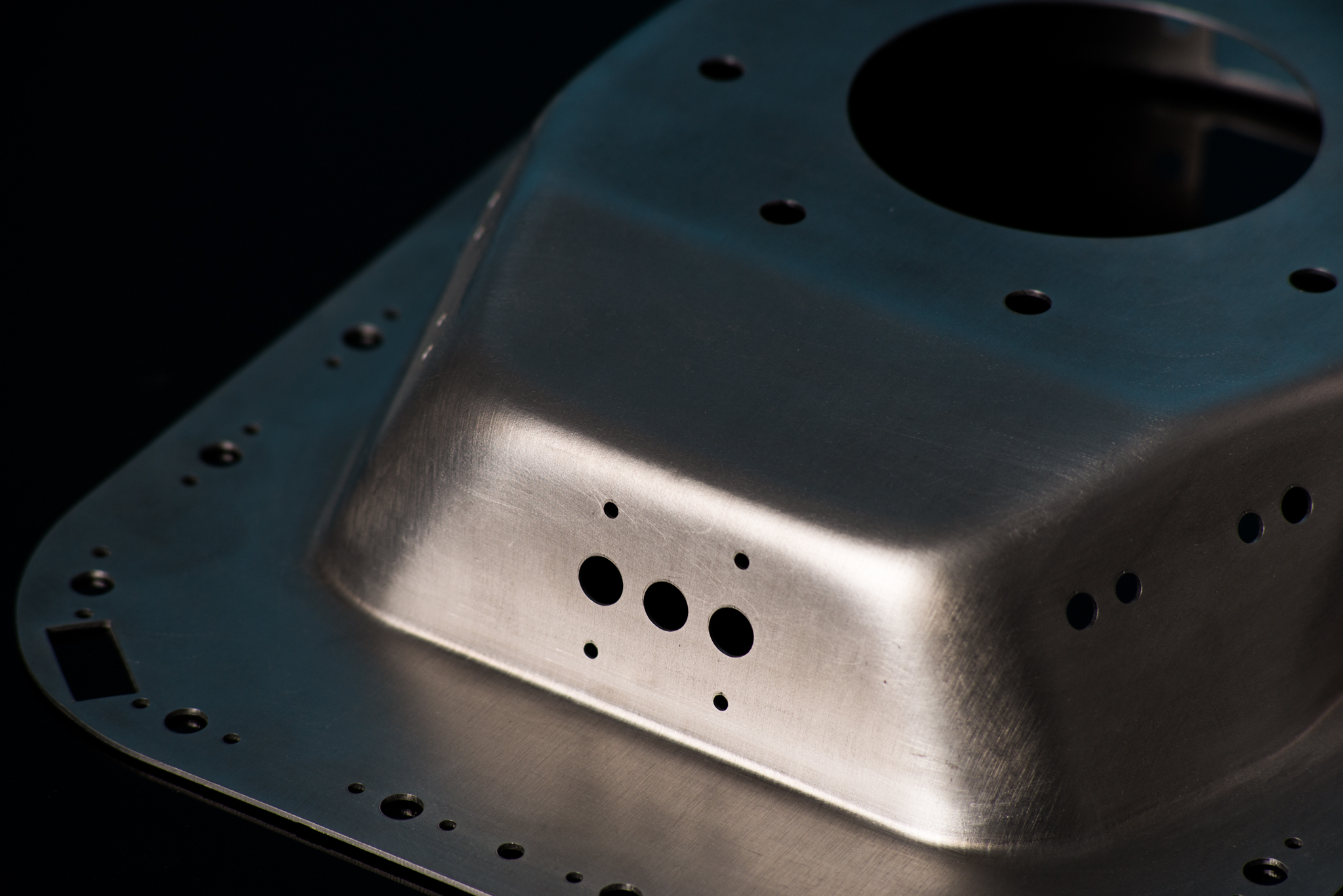

Impresa uses the hydroform process to produce large sophisticated parts including fuselage frames.

Cost effective way to form sheet metal in addition to the strengthening of the metal.

It is the preferred technique for shaping intricate components from ductile metals.

Cost savings hydroforming services allows customers to cut down on upfront costs associated with traditional metal forming and stamping because the process eliminates the need for expensive dies cast plastics for prototyping hardened steel tools and hard epoxy.

With a 24 diameter forming area and 5 000psi of forming pressure in a 58 x 100 flush floor design jinpao s triform press offers versatility without the need for.

Typical materials fabricated in sheet metal hydroforming include steel aluminum brass copper titanium and high temperature alloys.

With up to 4x the pressure used by traditional hydroforming devices highly complex parts which can be formed with ease.

For more than 40 years hydroform usa has led the way in all sheet metal applications by employing lean practices to manage large build packages including stretch forming brake and roll forming hydro forming cnc machining and chem paint.

Hydroforming is a quick efficient and reasonably priced metal forming technique that produces structurally strong components with minimum material wastage.

Hydroform hydroform presses are incredibly powerful delivering over 10 000 psi to achieve complex forming and tight tolerances.

Fluidforming s universal sheet metal and tube forming machine the formbalancer is a force contained structure that permits extremely high forming pressures of up to 400 mpa 60 000 psi.

We added our first hydroforming center to our avon ohio facility in 2008 and it s been our goal to keep expanding and innovating.

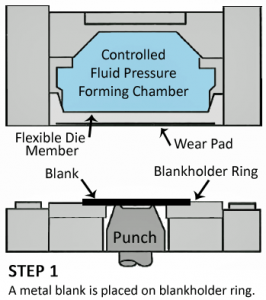

Sheet hydroforming is a metal forming process that uses pressurized hydraulic fluid in a flexible diaphragm to shape sheet metal against a single tool.